SET 2000

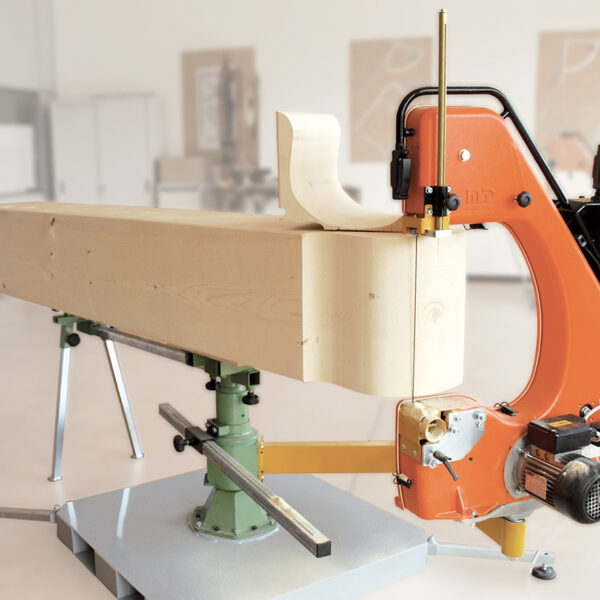

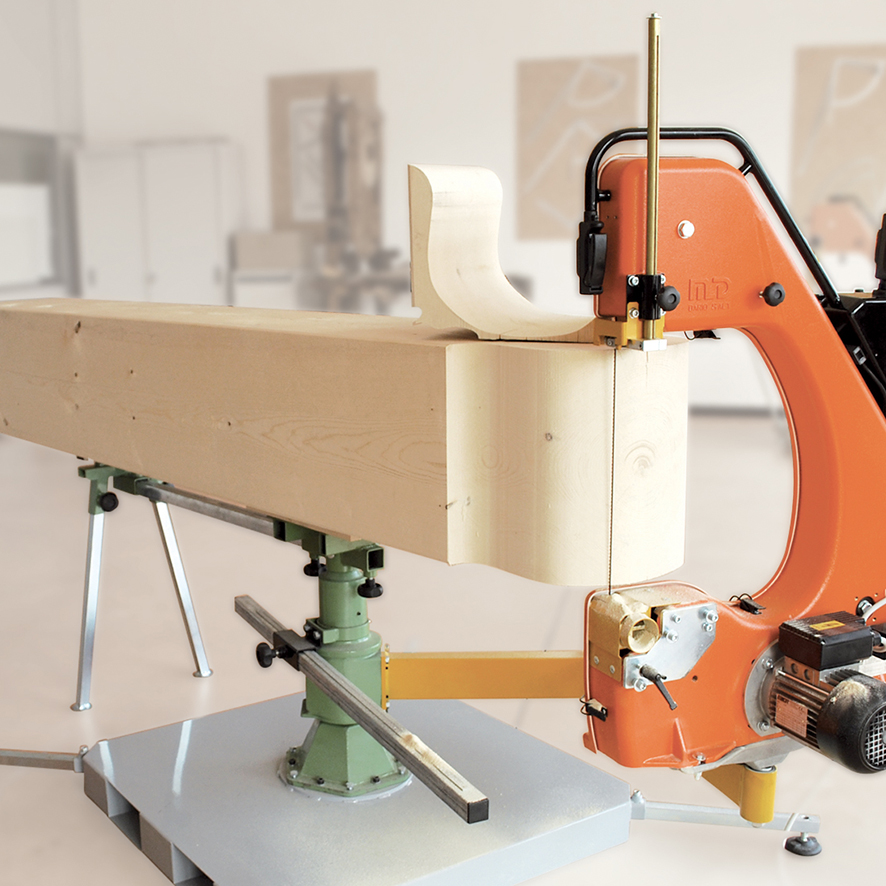

Nel SET2000, grazie alla colonna centrale, principale caratteristica di questo modello, la macchina è in grado di effettuare una rotazione a 360°. Il SET è particolarmente indicato per chi necessita di libertà di movimento o per eseguire tagli circolari.

Il SET 2000 è composto da:

- SEGATRICE SN33 O SN44

- COPIATORE

- PROTEZIONE A SOFFIETTO

- DOPPIA MANOPOLA

- BRACCIO SNODABILE BS600 LEGGI DI PIÙ

- COLONNA

- DISPOSITIVO TAGLIA ARCHI

- SUPPORTO MATERIALE CON CASTELLETTO

- PRESSORE P-250

DATI TECNICI

| SN33 LEGGI DI PIÙ | SN44 LEGGI DI PIÙ | |

| Larghezza di taglio | 15″ (390 mm) | 15″ (390 mm) |

| Altezza di taglio | 10″ (250 mm) | 14″ (350 mm) |

| Max altezza di taglio con soffietto speciale | 12″ (310 mm) | 16″ (410 mm) |

| Dimensioni piano di lavoro | 19″ x 16″ (500 x 400 mm) | 19″ x 16″ (500 x 400 mm)) |

| Lunghezza lama | 100″ (2530 mm) | 107″ (2720 mm) |

| Larghezza lama (minima) | 0.11″ (3 mm) | 0.11″ (3 mm) |

| Potenza motore | 1.5 HP – 1.1KW | 1.5 HP – 1.1KW |

| Peso | 353 lb (160 Kg) | 364 lb (165 Kg) |

*Le tolleranze di taglio, che dipendono dal tipo di lama utilizzata e dalle altezze di taglio, sono da considerarsi come quelle di normali segatrici a nastro. L’utilizzo della lama non assicura tolleranze inferiori a ± 2mm.

CARATTERISTICHE DEL PRODOTTO

ACCESSORI AGGIUNTIVI

Pedana mulettabile – Fissando la colonna BC800 sulla pedana mulettabile, è possibile spostare il SET2000 facilmente con un transpallet, evitando fissaggi a terra con inutile ingombro di spazio.

SR700 – Il dispositivo inclinabile permette di inclinare manualmente la macchina di 45°. La regolazione si effettua facilmente grazie ad un volantino graduato. Va considerato che l’aumento dell’inclinazione riduce la luce di taglio della segatrice.

Braccio snodabile prolungato – Il braccio prolungato BS600EX, che arriva ad una estensione di 165 cm permette di tagliare circonferenze con un raggio massimo di 143 cm.

A seconda delle dimensioni del pezzo da lavorare e/o contornare è possibile personalizzare la lunghezza del braccio snodabile.

ST100 – Il Dispositivo taglia tronchetti permette la realizzazione di tagli sagomati su tronchi a sezione circolare di varie dimensioni con un sistema veloce e preciso. Ideale per costruzioni ad incastro e utilizzato per la realizzazione di case in legno, staccionate, fioriere ed elementi di arredo urbano e decorativo

DPC 350 – Pressore girevole doppio – Indicato per la realizzazione di circonferenze di grandi dimensioni. La sua struttura garantisce stabilità ed evita la flessione dei tubi.

DISPOSITIVI SPECIALI

Dispositivo taglia selle– Il dispositivo taglia selle è ideato per la realizzazione di selle di diverse raggiature.

Applicato alla colonna del SET2000, prevede uno speciale supporto materiale completo di appositi pressori.

La misura del supporto può variare in base alla dimensione delle selle da realizzare. Il raggio della sella è regolabile tramite una barra metrica applicata alla segatrice.

Per particolari lavorazioni è possibile applicare l’avanzamento materiale e/o il sistema anticaduta.

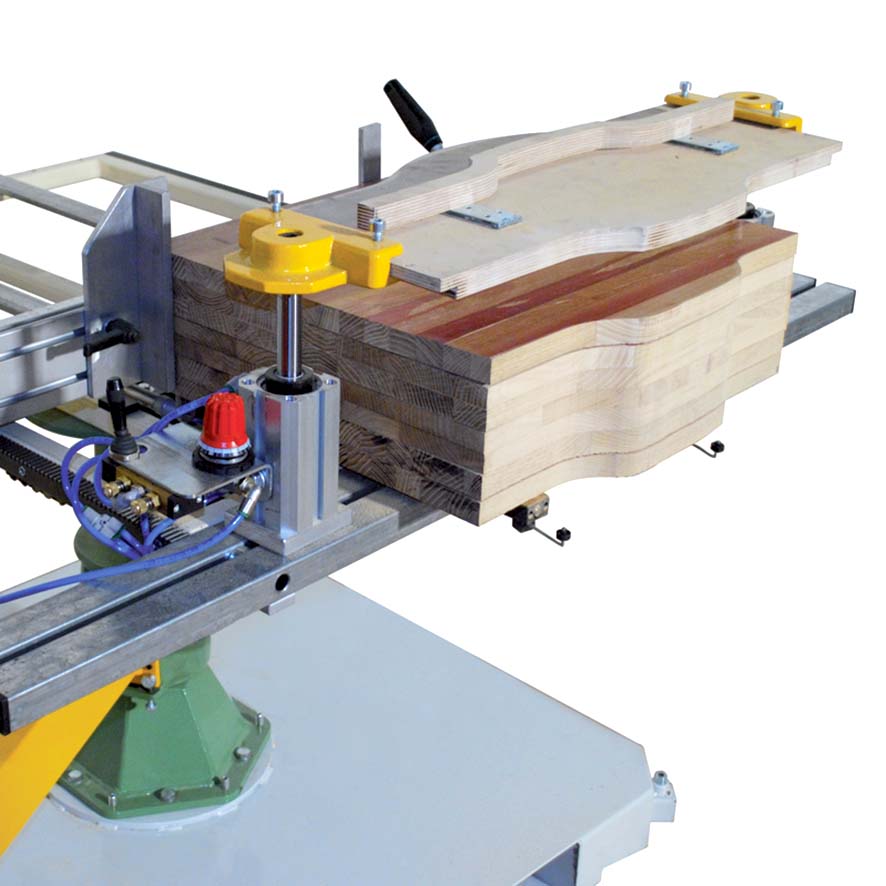

Supporto Pneumatico – Il supporto pneumatico permette di bloccare e tagliare più pezzi contemporaneamente (es. travi, pannelli, ecc) ed è stato studiato per eseguire tutte le lavorazioni di sagomatura per esigenze diverse: selle per trasporto tubi, antine, colonne, gambe per sedie, ecc.

Applicando una dima è inoltre possibile agevolare e velocizzare la fase di taglio.

Supporto Pneumatico e avanzamento materiale – E’ uno speciale supporto pneumatico per il taglio a pacco dei pannelli con l’aggiunta del sistema di avanzamento del materiale. Una volta eseguita la lavorazione, tramite un sistema meccanico e manuale, si permette l’avanzamento del materiale, mentre il sistema di anticaduta evita che i pezzi sagomati cadano a terra.

Per questo dipositivo si prevede l’uso della dima.

Doppia colonna – E’ possibile aggiungere al SET2000 una colonna supplementare che permette di fissare pezzi di lunghe dimensioni che devono essere sagomati su entrambi i lati.

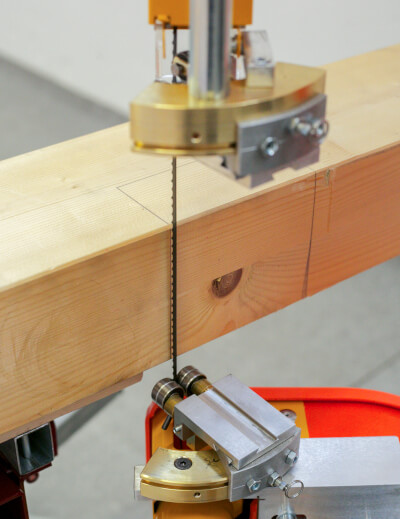

Guida per lama a rotazione manuale – Questo speciale dispositivo permette all’operatore di ruotare la lama di 30° e sagomare la parte centrale del pezzo di legno con tagli a 90°. Questo accessorio evita che la sega si schianti contro la trave.

Giostra – È un supporto pneumatico a 4 stazioni di lavoro. Qualora il lavoro preveda l’utilizzo di dime diverse, il dispositivo pneumatico a giostra permette di passare da una lavorazione all’altra spostandosi nelle diverse postazioni, per un totale di 4 postazioni massimo. Non è previsto l’avanzamento del materiale..

Supporto a farfalla – Lo speciale supporto pneumatico a doppia stazione è la soluzione ideale per chi necessita di tagliare parti sagomate su più pannelli nel minor tempo possibile. Dotato infatti di un pressore pneumatico che ne blocca il materiale, permette al sovrapposizione di più pannelli assieme fissandoli dall’alto con la sagoma da eseguire. Grazie al copiatore posto attorno alla lama, si segue manualmente la sagoma realizzando il taglio desiderato. Mentre da un lato l’operatore esegue il taglio, dall’altro un secondo operatore può cambiare il materiale già lavorato e preparare il materiale per il taglio successivo, con un notevole risparmio di tempo.