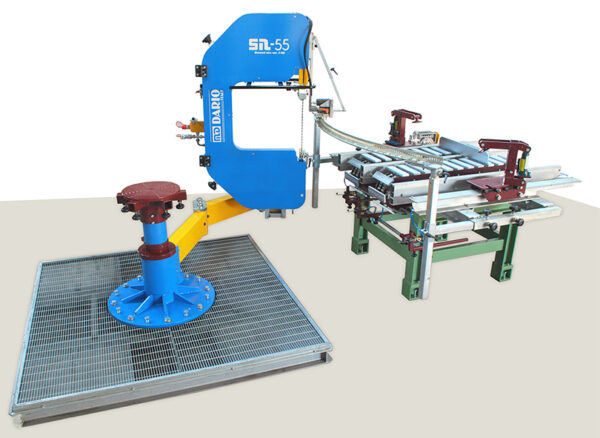

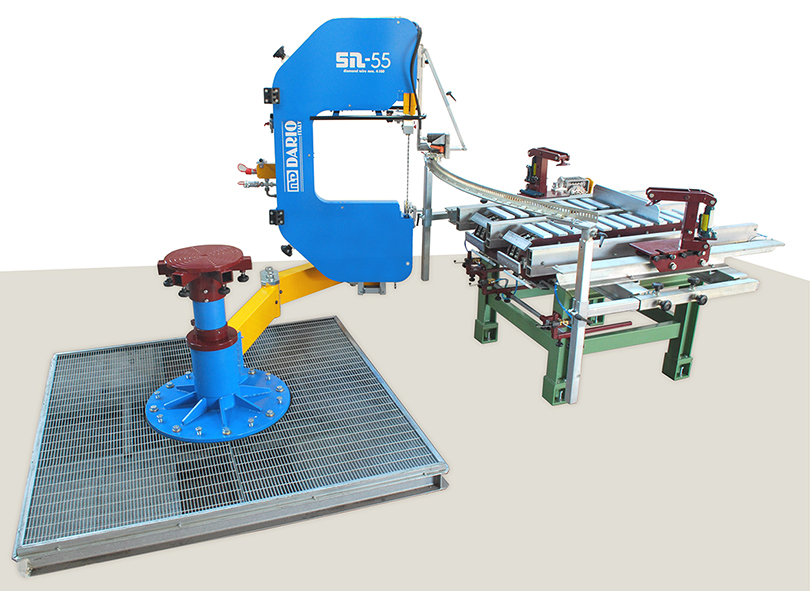

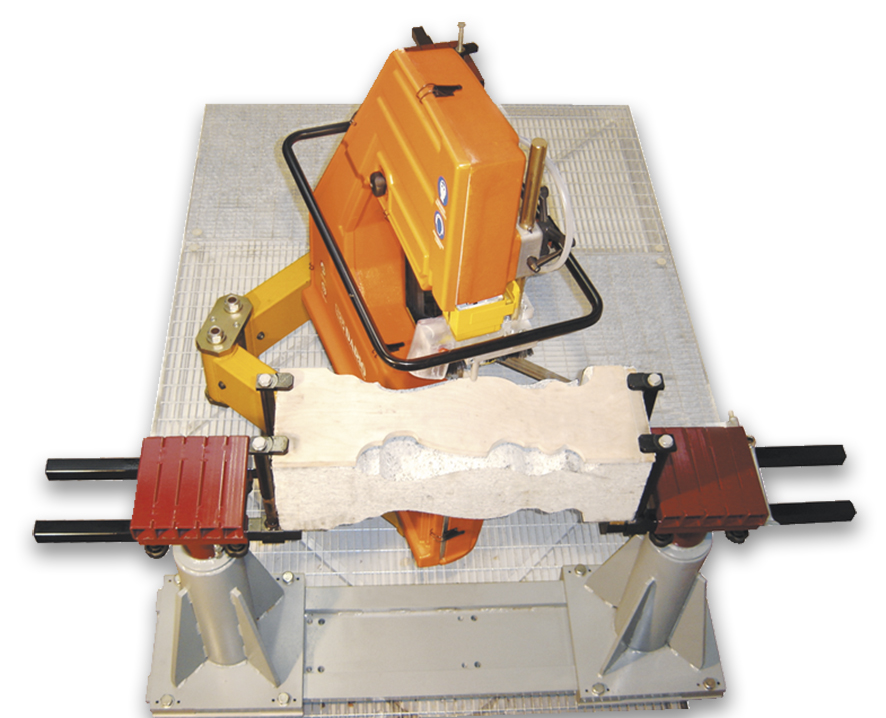

SET 600

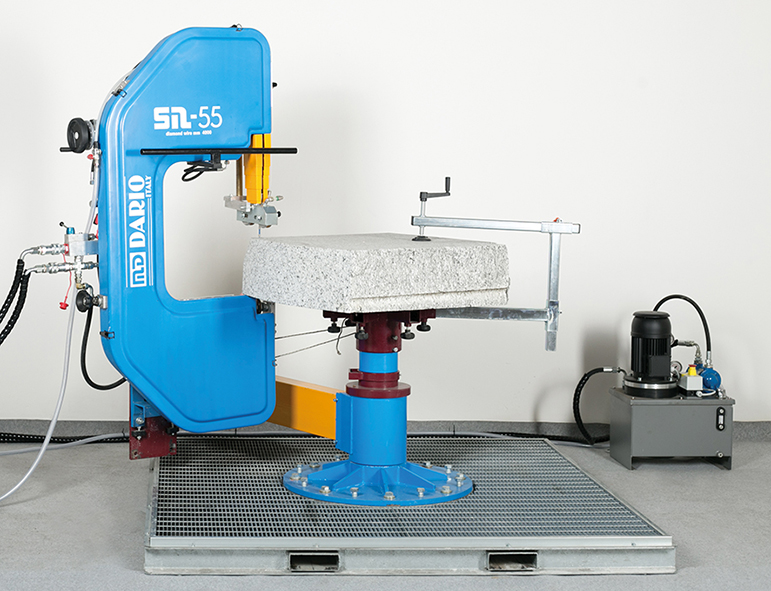

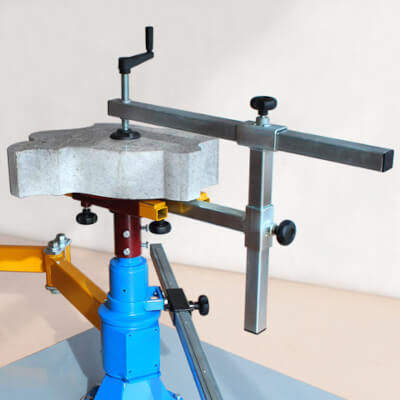

Suggested for those who need to work pieces of big dimensions of marble and granite, it has been developed to realize shaped works, curves and arcs.

SET600 involves new mechanical components: new is the articulated arm with two swivel connections BS1000, and new is also the tilting device SR1000, more structured and stable in comparison with the previous model SR900. SET 600 includes:

- SAW SN55

- COPYING DEVICE

- BELLOW PROTECTION SYSTEM

- ARTICULATED ARM BS1000 READ MORE

- COLUMN

- ARC CUTTING DEVICE

- HYDRAULIC MOTOR WITH ADJUSTABLE SPEED

- TILTING DEVICE SR100

- MATERIAL SUPPORT

- PRESSURE LOCK P-250

TECHNICAL DATA

| SN55 | |

| Cutting width | 19″ (490 mm) |

| Wire lenght | 157″ (4000 mm) |

| Cutting height | 21.5″ (550mm) |

| Arm length | Maximum radius 78″ (200 cm) |

| Hydraulic motor | Adjustable speed |

*The cutting heights are approximate, considering a professional and daily use of the machine. Cutting capacity thickness depends on the material type.

**Cutting speed depends on the type of material, the cutting height and the diamond wire employed.

PRODUCT FEATURES

ADDITIONAL ACCESSORIES

Platform 200 x 200 cm – The platform 200 x 200cm ensures a bigger working area. The use of grid platform guarantees the water drainage and a higher stability and safety for the operator.

This kind of platform can be moved using a forklift, but not a pallet truck.

Upon request, MD DARIO can supply also the tank for water drainage model AQ-090, to use in combination with water recycling devices.

Extra column – It is possible to add to SET400 an extra column, to fix the piece to cut and realize arcs and shapes working on both sides, without moving the piece. MD DARIO® suggests the combined use of the grid platform 300 x 200 cm.

Automatic Arc Cutting Device – The automatic arc cutting device allows the automatic advance of the saw STM400. This device involves the use of arc templates (available in different radius) and it is suggested for those who need to cut several pieces in series (for example street curbs).

The saw automatically follows the template and the operator is needed just to remove the piece that has been cut.